Machine Nirvana: CNC Mill Winter Workshop

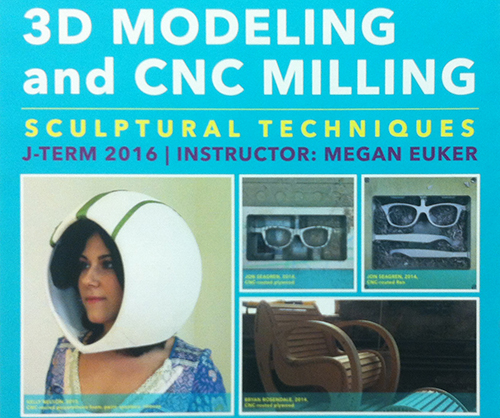

The poster that caught my attention as soon as I saw it…

Last week I took a one-credit class that I’ve been eyeing for a while now: CNC Milling and Modeling. Columbia has a nice long winter break, but there are some classes scheduled during the J-term (what we call the winter period). When I heard this class was going to be offered over the break, I jumped. CNC milling is a “computer numeric controlled” process for milling objects, using instructions given from code generated by 3-D software. The mill itself is a large, noisy, industrial machine—in other words, my favorite!

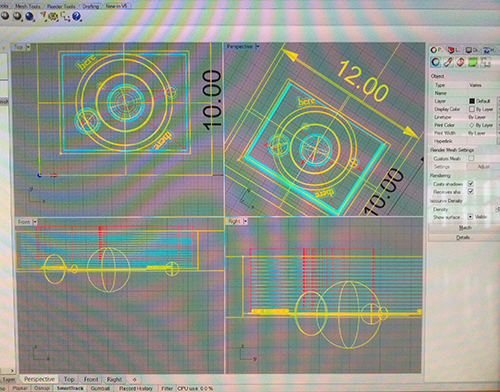

A screen grab of a prototype I worked on in Rhino

I love machines and tools. When I was getting my BFA, I learned how to weld, and that took my art in a new direction. I haven’t looked back. Before, I had mostly done digital work in sound and video, and then welding came along and sparked my interest in 3-D objects. When I started, I made some standalone objects, but nowadays I make objects usually as part of an installation.

For this class we used Rhino, a software that allows artists to make 3-D objects in digital space. I had used some other software when I took a 3-D Printing class, but nothing quite as intense as Rhino. Digital 3-D projects are much, much more labor-intensive than 2-D projects, and the software that creates them are pretty intense. I was really glad that I had some experience in digital 3-D files before the CNC milling class, because the learning curve is steep. Fortunately our instructor, Megan Euker, knows the software and the milling process inside and out, and was really good at helping everyone with their projects.

Fellow students

There were about 10 of us in the class, including myself (the only grad student) and 4 art professors. The rest of the students were undergrads. The class was technically an undergrad course, but I don’t think they let anyone near the machine unless they’ve taken the workshop, so the participants included anyone who wants access to the mill. In order to make it a grad-level class, I had to take the course as an independent study and then complete additional work beyond what’s on the undergrad syllabus. It was fun to mix with a diverse group. This is the only experience I’ve had like that here—usually it’s grad students only in my classes.

The machine itself is seriously impressive, and has its very own room in the Fabrication Facility. The bed is 4’x8′, so you can put any material that fits into it to be milled. We used foam and wood in our prototypes, but the machine could also mill materials like plastics or metals, which is what I have in mind. I’ve used the laser cutter quite extensively, but that only makes cuts that create essentially 2-D objects. Also, since the laser actually burns through the material, there are a lot of restrictions about what kind of material you can use. The exhaust can get really toxic, even with a closed hood whisking it away. The CNC mill uses drill bits to carve objects, so there is very little worry about toxicity, which is fabulous.

A student watches her prototype being milled

I have to finalize what I am going to use the CNC mill for in terms of my thesis project. The thesis exhibition is in May, so I have a little time to figure it out, but time seems to dash by, especially in my last year. However, I know that one of the makerspaces in town (it’s called Pumping Station One) has a CNC mill, so I know after I graduate I can still mill objects. I’ve gained a lot of technical skills in graduate school, and I’m excited about using them in my art career!